![PBG [Polygon Ball Guide]](../images/newproduct/title_09.gif) Technical inquiry sheet

Technical inquiry sheet

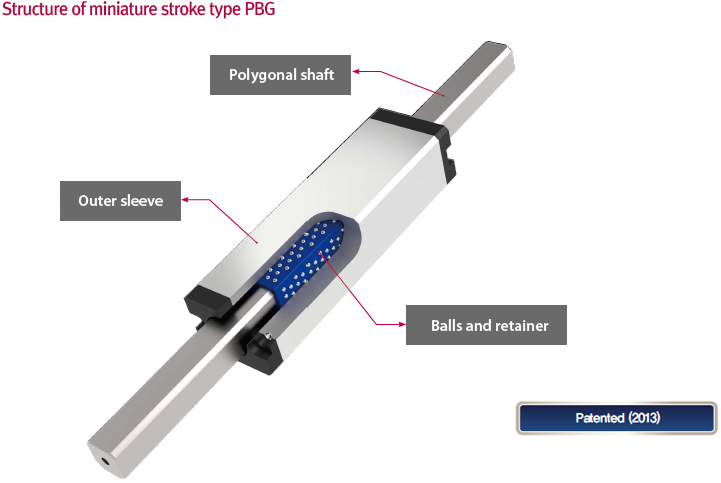

Structure and Features

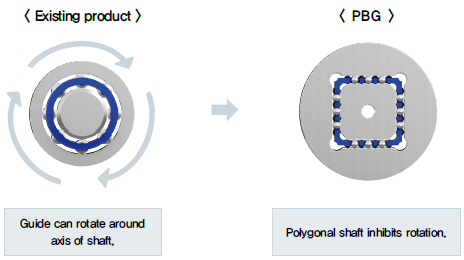

PBG consists of a polygonal shaft, precision balls, retainer, and outer sleeve. Multiple configurations are available depending on application needs. The polygonal shaft and inner surface of the outer sleeve virtually eliminate rotation.The high ball count ensures smooth motion and high rigidity with minimal clearance.

1) High precision and rigidity : Point contact between the balls and the mirror-polished polygonal shaft and inner surface of the sleeve ensures straightness, smooth motion, and essentially zero rotation. This maintains stability and accuracy by minimizing yawing, rolling, and pitching. The high ball count between the two surfaces also maintains rigidity.

2) Minimal resistance : Point contact between balls and mirror-polished surfaces results in low friction and minimal loss of rolling movement.

3) Stable and fast performance : Polygonal ball arrangement allows a preload of several μm to achieve improved rigidity and straightness. This reduces looseness and incidental vibration and shock, for stable accuracy and smooth motion.

4) Compact design : High number of small-diameter balls in a low-profile retainer keeps the OD small, the design compact, and minimizes weight.

Uses

Ideal for systems transporting small, precision parts, such as: small precision measuring instruments; OA equipment; sorters for semiconductors, LED chips, or small lensesPBG Round Standard Type

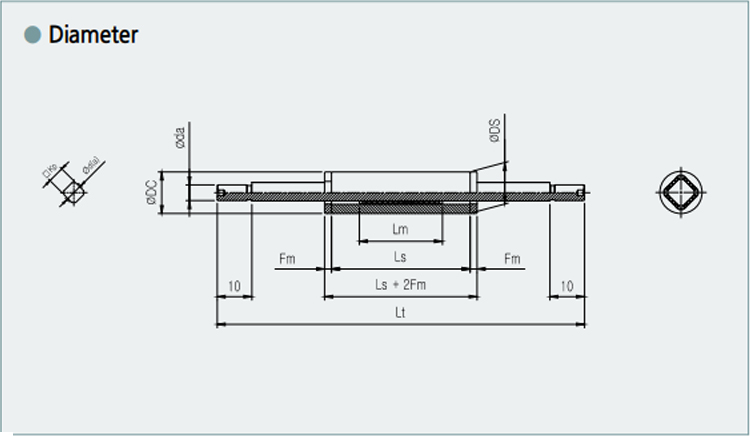

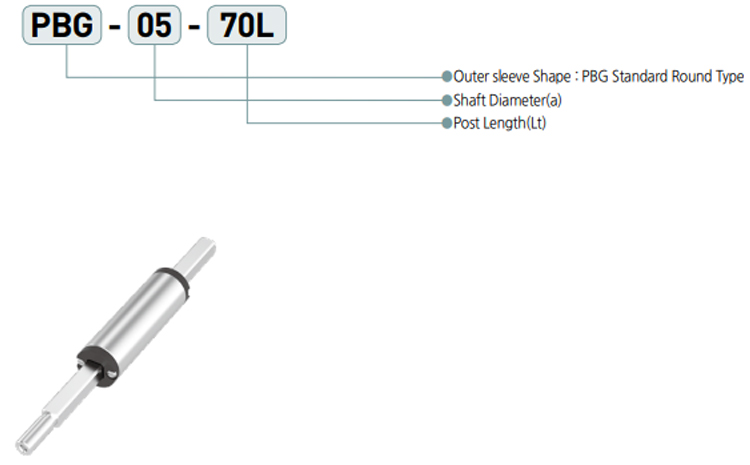

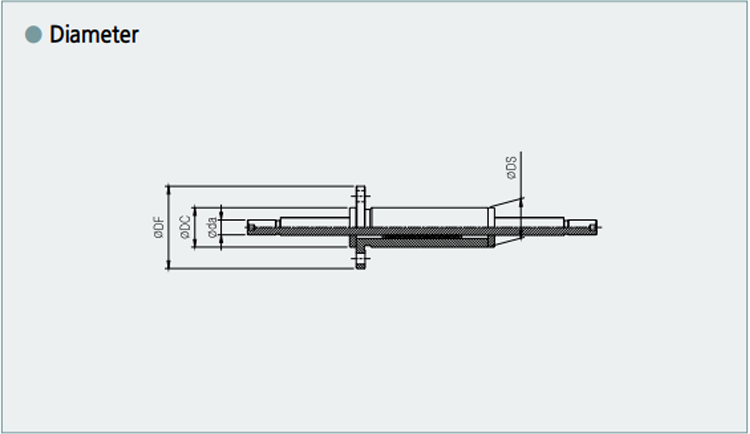

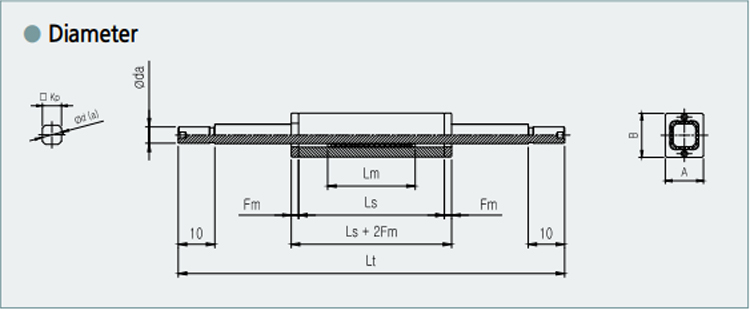

Diameter

Model number notation

| Model | ㅁKp | Ød | ØDC | ØDS | Øda | Lm | Ls | Fm | Lt | BALL(Ø) | Co(N) | C(N) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PBG-05 | 4 | 5 | 10 | 10 | 4 | 22 | 30 | 2 | 70 | 0.6 | 250 | 180 |

| PBG-06 | 4.7 | 6 | 12 | 12 | 4.5 | 24 | 40 | 2 | 86 | 1.0 | 380 | 350 |

| PBG-09 | 7.8 | 9.4 | 15 | 15 | 6 | 24 | 40 | 2 | 104 | 570 | 440 |

Note1) Stroke = (Outer sleeve length(Ls) - Retainer length(Lm)) x 2

Note2) Main unit : mm

Note3) 1N ≒ 0.102kgf

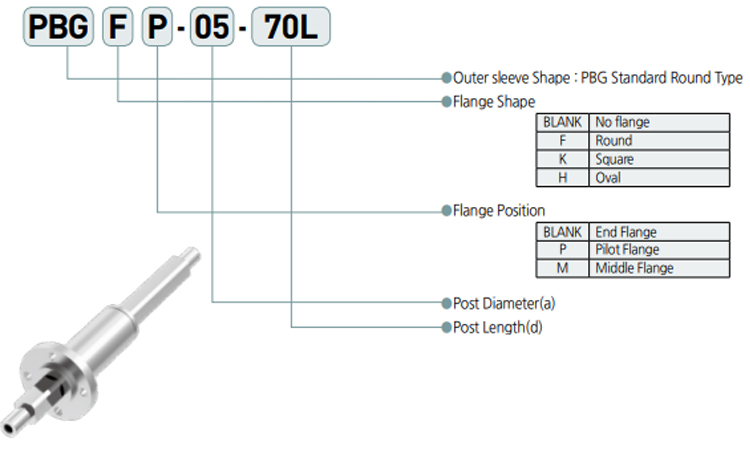

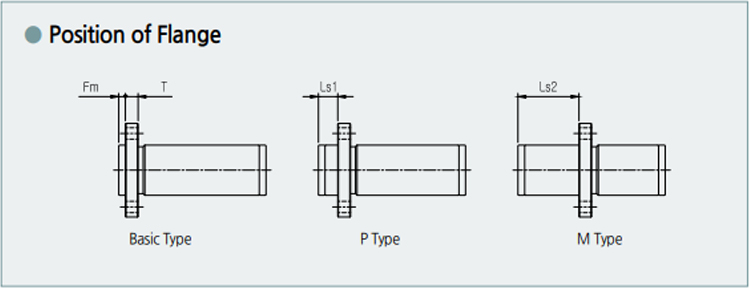

PBG Round Flange Type

Diameter

Model number notation

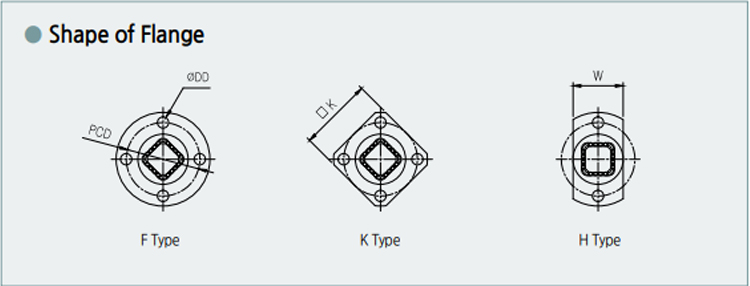

| Flange Type | ØDF | ØDD | PCD | ØDS | ㅁK | W | T | Fm | Ls1 | Ls2 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Round | Square | Oval | ||||||||||

| PBGF-05 | PBGK-05 | PBGH-05 | 23 | 3.4 | 17 | 10 | 18 | 10 | 2.7 | 2 | - | - |

| PBGFP-05 | PBGKP-05 | PBGHP-05 | 23 | 3.4 | 17 | 10 | 18 | 10 | 2.7 | - | 4.7 | - |

| PBGFM-05 | PBGKM-05 | PBGHM-05 | 23 | 3.4 | 17 | 10 | 18 | 10 | 2.7 | - | - | 14.3 |

| PBGF-06 | PBGK-06 | PBGH-06 | 25 | 3.4 | 19 | 12 | 20 | 12 | 2.7 | 2 | - | - |

| PBGFP-06 | PBGKP-06 | PBGHP-06 | 25 | 3.4 | 19 | 12 | 20 | 12 | 2.7 | - | 4.7 | - |

| PBGFM-06 | PBGKM-06 | PBGHM-06 | 25 | 3.4 | 19 | 12 | 20 | 12 | 2.7 | - | - | 19.3 |

| PBGF-09 | PBGK-09 | PBGH-09 | 28 | 3.4 | 22 | 15 | 22 | 15 | 3.8 | 2 | - | - |

| PBGFP-09 | PBGKP-09 | PBGHP-09 | 28 | 3.4 | 22 | 15 | 22 | 15 | 3.8 | - | 5.8 | - |

| PBGFM-09 | PBGKM-09 | PBGHM-09 | 28 | 3.4 | 22 | 15 | 22 | 15 | 3.8 | - | - | 18.2 |

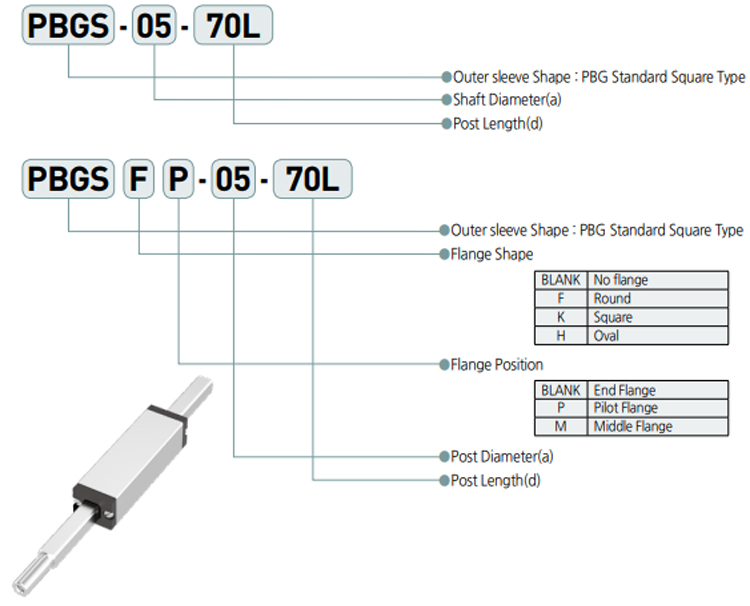

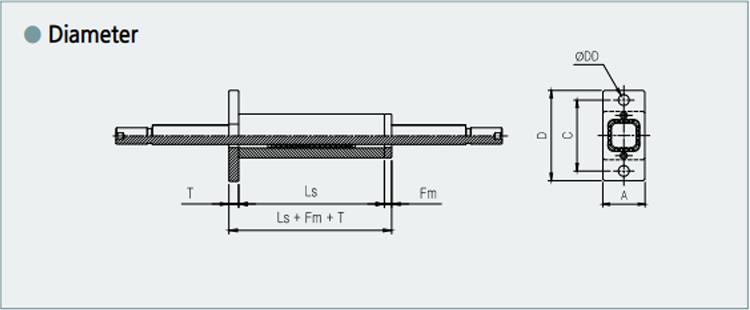

PBGS Square Standard Type

Diameter

Model number notation

PBGSK Square Standard Type

| Model | Ls | Fm | A | B | C | D | T | ØDD | Lm | Lt | Ød | ㅁKp | BALL(Ø) | Co(N) | C(N) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PBGS-05 | 30 | 2 | 8 | 10 | - | - | - | - | 22 | 70 | 5 | 4 | 0.6 | 250 | 180 |

| PBGSF-05 | 30 | 2 | 8 | 10 | 17 | 23 | 2.7 | 3.4 | 22 | 70 | 5 | 4 | |||

| PBGS-06 | 40 | 2 | 10 | 12 | - | - | - | - | 24 | 86 | 6 | 4.7 | 1.0 | 380 | 350 |

| PBGSF-06 | 40 | 2 | 10 | 12 | 19 | 25 | 2.7 | 3.4 | 24 | 86 | 6 | 4.7 | |||

| PBGS-09 | 40 | 2 | 13 | 15 | - | - | - | - | 24 | 104 | 9.4 | 7.8 | 570 | 440 | |

| PBGSF-09 | 40 | 2 | 13 | 15 | 22 | 28 | 3.8 | 3.4 | 24 | 104 | 9.4 | 7.8 |

| Flange Type | ØDF | ØDD | PCD | ㅁK | W | T | Ls1 | Ls2 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Round | Square | Oval | ||||||||

| PBGSF-05 | PBGSK-05 | PBGSH-05 | 23 | 3.4 | 17 | 18 | 10 | 2.7 | - | - |

| PBGSFP-05 | PBGSKP-05 | PBGSHP-05 | 23 | 3.4 | 17 | 18 | 10 | 2.7 | 4.7 | - |

| PBGSFM-05 | PBGSKM-05 | PBGSHM-05 | 23 | 3.4 | 17 | 18 | 10 | 2.7 | - | 14.3 |

| PBGSF-06 | PBGSK-06 | PBGSH-06 | 25 | 3.4 | 19 | 20 | 12 | 2.7 | - | - |

| PBGSFP-06 | PBGSKP-06 | PBGSHP-06 | 25 | 3.4 | 19 | 20 | 12 | 2.7 | 4.7 | - |

| PBGSFM-06 | PBGSKM-06 | PBGSHM-06 | 25 | 3.4 | 19 | 20 | 12 | 2.7 | - | 19.3 |

| PBGSF-09 | PBGSK-09 | PBGSH-09 | 28 | 3.4 | 22 | 22 | 15 | 3.8 | - | - |

| PBGSFP-09 | PBGSKP-09 | PBGSHP-09 | 28 | 3.4 | 22 | 22 | 15 | 3.8 | 5.8 | - |

| PBGSFM-09 | PBGSKM-09 | PBGSHM-09 | 28 | 3.4 | 22 | 22 | 15 | 3.8 | - | 18.2 |

Note1) Stroke = (Outer sleeve length(Ls) - Retainer length(Lm)) x 2

Note2) Square type of PBGS is only available with Square type Flange

Note3) End-flange type only possible for PBGSK

Note4) Main unit : mm

Note5) 1N ≒ 0.102kgf

video

Technical inquiry sheet * Please print out the download file, fill in the necessary information, and contact us by FAX or E-mail.