> Overview

Guide Master SGM Series Overview

New Precision Guide Posts for Die/Mold and Punch Press Applications! SAMICK Precision Industries is Proud to Introduce a Technological Advance in Precision Guideance That Allows for Higher Loads, Greater Speeds, Superior Accuracy and Mechanical Stability. The SAMICK Guide Master SGM Revolutionizes Guide Post Linear Motion With an Octagonal Needle Roller Design that Guarantees Longer Life of Die Sets Over the Traditional Ball Products.

Guide Master SGM Series Feature and Benefits

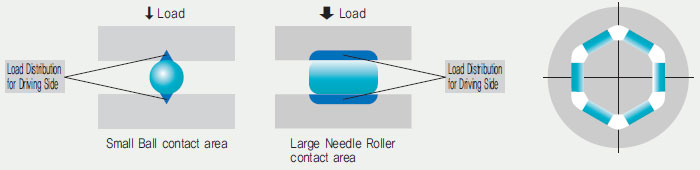

1.High Load Capacity

With 8rows of Needle Bearings in its Octagonal Design, Guide Master SGM has more Points of Contact Between Post and Sleeve Than the Traditional 4-Sided Styles. More Surface Area Contact Automatically Means the Benefit of Higher Load Capacity-up to 2 Times more Than Ball Products!

2.Superior Accuracy.

The Precision fit and Typical 4-6 ¥im Preload Between Post and Sleeve Gives the Smooth Motion of the Guide Master SGM Superior Accuracy Cycle After Cycle.

3.Increased Speed.

In Comparison to Ball-Type Guide Post, Guide Master SGM Leads the Race. The Finely Adjusted Preload and Octagonal Shape Minimizes Impact Loading and Vibration for Uninterrupted Operation. An Incredibly Fine Surface Finish of Ra 0.1 ¥im Makes Rapid Motion Effortless With Minimal Friction and no Slipping.

4.Longer Life.

The Guide Master SGM is Designed to Protect the Needle Bearings and Provide Continuous Lubrication. Resistant to Torques, Shocks, Thrusts, Vibration, Pitching and Turning, Guide Master SGM Stands by Itself, Easily Outlasting Ball Guide Posts With 10 Times Longer Life.

Guide Master SGM Applications

- Smt and Inspection Machinery (Semiconductor and LCD)

- Robotic Arms

- Slides and Stages

- Conveyance Equipment

- Punch Presses for Molds